Respiratory Protective Equipment (RPE) has long been a familiar sight on construction sites. Masks and respirators are often seen as the frontline defence against harmful dust, fumes and airborne particles. Yet every year in the UK construction industry, thousands of workers develop irreversible lung disease due to exposure to dust at work.

It is becoming increasingly clear that RPE alone is not enough.

To truly protect workers and meet legal obligations, construction businesses must look beyond personal protection and take control of the air itself.

Invisible Threat You Can’t See

Construction activities such as cutting concrete, stone, tiles and masonry generate fine dust particles small enough to penetrate deep into the lungs. Known as respirable crystalline silica (RCS), these particles are invisible to the naked eye but extremely dangerous when inhaled, causing devastating long-term health effects.

According to the Health and Safety Executive (HSE) estimates, more than 500 construction workers in the UK die every year from diseases linked to dust exposure.

High-risk dust is commonly generated by power tools such as:

- Cut-off saws

- Grinders

- Wall chasers

- Sanding and drilling equipment

These tools can produce very high concentrations of fine dust in seconds. The particles are often up to 100 times smaller than a grain of sand, allowing them to travel deep into the lungs where the body cannot remove them.

Unlike larger, inhalable dust particles that are often trapped in the upper airways, respirable dust lodges deep within the lungs. At this point, even small failures in RPE, such as poor fit, leaks, or incorrect use, can result in significant exposure.

Over time, repeated exposure can lead to:

- Silicosis

- Chronic Obstructive Pulmonary Disease (COPD)

- Lung cancer

- Occupational asthma

Crucially, this damage is cumulative and irreversible. Workers may not notice symptoms for years, but by the time they do, the harm has already been done.

Taking Control is a Smarter, Safer Approach

To reduce risk effectively, construction sites must focus on capturing and filtering dust before it spreads. For high-dust construction activities, a robust, high-capacity filtration unit is essential to reduce airborne dust at source and protect everyone in the work area, not just the individual wearing a mask.

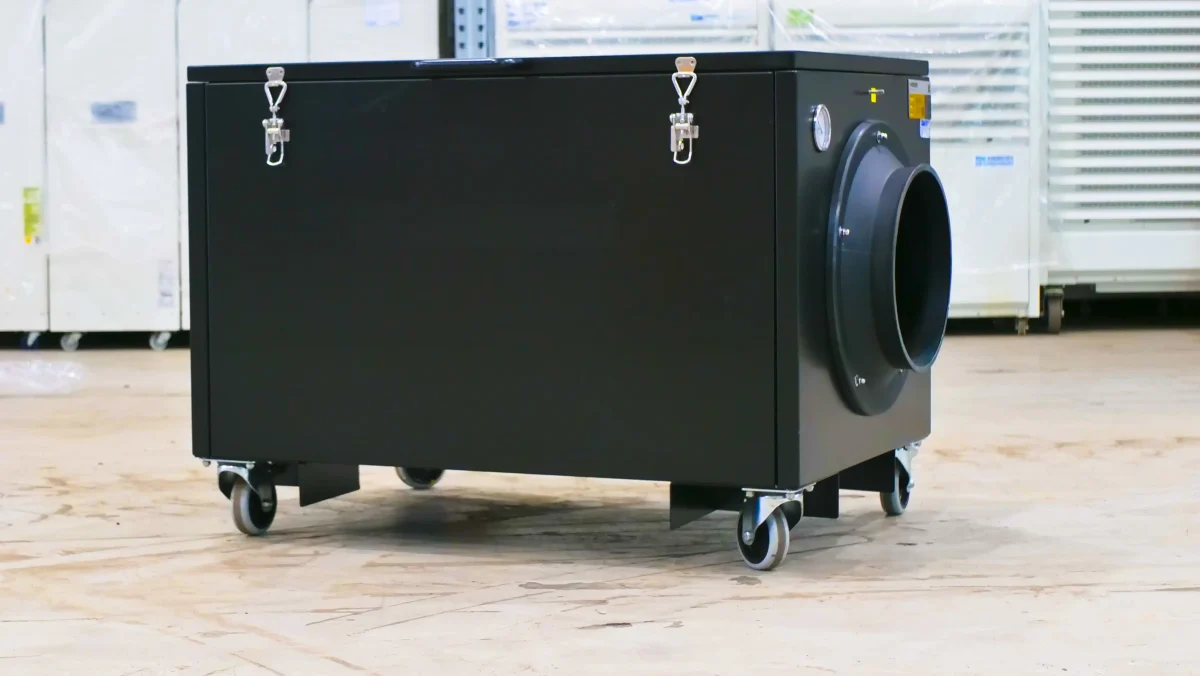

Filterbox Maxi Air Filtration Unit

Filterbox Maxi is specifically designed for demanding construction environments where high volumes of dust are generated. Providing high-capacity, multi-stage filtration, the unit can be configured to suit the task at hand whether controlling silica dust, welding fumes or odours from coatings and treatments.

With airflow up to 2500 m³/hr, the Filterbox Maxi rapidly filters contaminated air in enclosed or semi-enclosed work zones, helping reduce respirable dust concentrations quickly.

As multi-stage filtration includes HEPA, the system can be configured with:

- H14 HEPA filters

- ATEX G4 pre-filters

- Particulate filters

- Activated carbon filters

This makes it suitable for controlling fine respirable silica dust, ensuring even the smallest hazardous particles are captured before they can be inhaled.

Suitable for Hazardous and ATEX Zones 1 & 2

Many construction activities such as tunnelling, civils works and certain refurbishment projects, may involve hazardous atmospheres. The Filterbox Maxi has undergone ignition hazard assessment and is suitable for use in ATEX environments, providing reassurance where safety standards are critical.

The system can be connected inline with 300 mm or 400 mm ducting and integrated into temporary negative pressure setups, making it ideal for:

- Concrete cutting zones

- Stone and tile works

- Quarrying operations

- Enclosed demolition areas

- Tunnelling projects

For large-scale or high-intensity dust generation, the Filterbox Maxi provides a powerful engineering control that significantly reduces reliance on RPE alone.

Filterbox Mini Air Filtration Unit

Where space is limited or work is taking place within occupied or partially enclosed environments, the Filterbox Mini Air Filtration Unit offers a compact yet highly effective solution.

Despite its smaller footprint and lightweight design, it delivers airflow up to 3000 m³/hr and can be configured with the same high-performance filtration options as the Maxi.

Weighing just 23 kg with filters, it is compact enough to be carried by two operatives and is ideal for short-term tasks, rapid deployment and mobile site operations.

When fitted with an H14 HEPA filter, the unit captures extremely fine respirable particles making it particularly effective during:

- Internal fit-out works

- Refurbishment projects

- Localised cutting and chasing

- M&E installations

The Mini is also suitable for hazardous environments. When used with ducting and extraction hoods, it helps create controlled dust zones, preventing contamination of surrounding work areas.

Which Unit Should You Choose

| Specification | Filterbox Mini | Filterbox Maxi |

| Primary Use | Compact dust & fume extraction for confined or localised works | Heavy-duty dust & fume extraction for large-scale construction |

| Maximum Airflow | 3000 m³/h | 2500 m³/h |

| Filtration Stages | 2-stage filtration | 3-stage filtration |

| Filter Configurations | Welding, Dust, HEPA | Welding, Dust, Paint, HEPA |

| ATEX G4 Pre-Filter Particulate Filter Activated Carbon Filter H14 HEPA Filter | ✓ ✓ ✓ ✓ | ✓ ✓ ✓ ✓ |

| Construction Suitability | Refurbishment, internal fit-out, chasing, short-duration cutting works | Concrete cutting, tunnelling, quarrying, civils, demolition zones |

➣ Choose Filterbox Maxi when managing high-volume dust generation, large work zones, or heavy-duty outdoor construction projects.

For full technical details and hire options: https://www.andrews-sykes.com/air-quality/dust-fume-extraction-equipment-hire/filterbox-maxi-air-filtration-unit/

➣ Choose Filterbox Mini for confined spaces, internal works, rapid deployment tasks, or when portability is critical.

For full technical details and hire options: https://www.andrews-sykes.com/air-quality/dust-fume-extraction-equipment-hire/filterbox-mini-air-filtration-unit/

Both units support compliance with COSHH hierarchy of control by helping remove respirable dust at source by reducing reliance on RPE alone.

Future of Construction Dust Control

The construction industry has made significant progress in recognising the dangers of asbestos. The same level of seriousness must now be applied to respirable construction dust.

While RPE remains essential, it should be considered the last line of defence, not the primary control measure.

By combining education, correct PPE usage and effective engineering controls such as high-performance air filtration systems, construction businesses can significantly reduce the long-term health risks facing their workforce.

Need to find the perfect filtration system for your workspaces?

|

Andrews Air Quality friendly team members can help you choose the right temporary filtration solution for your site.

With the right planning and the right equipment, you can keep your project on track, protect your workforce, and ensure the quality of your work. Call 0800 211 611 or enquire online to find the best solution for your industry! |

|---|

FAQs

How do HEPA filters improve workplace air quality?

HEPA filters are designed to capture extremely fine particles, such as dust, allergens, bacteria and some airborne contaminants, down to microscopic sizes. In construction environments, HEPA filtration plays a critical role in controlling respirable silica dust. In offices and healthcare environments, HEPA systems help improve indoor air quality and reduce airborne transmission risks.

Our recent healthcare case study shows this in action, where industrial-grade HEPA air purifiers helped a hospital achieve 6 – 8 air changes per hour and create negative pressure zones to limit infection spread.

➣ Find out more about ‘Straightforward ventilation hire becomes dual-purpose healthcare solution’

How can I choose the right air filtration system for my site?

Our air quality specialists can assess your site requirements and recommend the most appropriate system whether that’s a heavy-duty dust extraction unit for construction or a portable HEPA air purifier for offices or healthcare facilities.

Call 0800 211 611 or enquire online to discuss your air quality requirements.

What industries benefit from temporary air filtration hire?

Temporary air filtration systems are widely used across multiple industries, including:

- Building and construction

- Healthcare and hospitals

- Manufacturing and warehousing

- Education and public buildings

- Commercial offices

- Retail and hospitality

Each environment presents a wide variety of challenges, which is why we offer scalable and portable air quality solutions tailored to different settings.