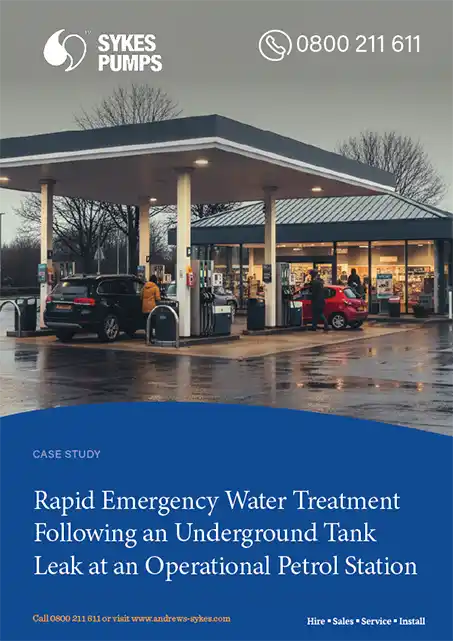

A national forecourt operator reported a sudden loss of volume from an underground storage tank used to store blended biofuel (diesel with FAME content). Over several days, the leak allowed fuel to migrate into the surrounding subsoil beneath the operational petrol station forecourt.

Following periods of heavy rainfall, contaminated groundwater and surface water began entering interceptor chambers, inspection pits, and surface water drainage systems, creating an immediate risk to surrounding land and nearby surface water outfalls. The client required a rapid-response water treatment system to contain and treat the contamination while maintaining full site operations.

The Sykes Pumps team provided a rapidly deployable, temporary water treatment solution. The objective was clear: contain the contamination, ensure regulatory compliance, and allow the petrol station to remain fully operational during remediation.

Complex Contamination & Restricted Footprint

This incident presented several technical and operational challenges that were successfully addressed by our dedicated engineers.

| Solubility Issues | The FAME content in modern biofuels increases water solubility, making standard oil-water separation more complex. |

| Variable Flows | Rainfall mobilised contaminated groundwater, creating intermittent, high-risk flows that required a system capable of handling fluctuating volumes. |

| Space Constraints | All mitigation equipment had to be installed within a restricted footprint on a busy, live forecourt. |

| Time-Critical Response | The solution needed to be operational within 24–48 hours to satisfy regulatory requirements. |

A Multi-Stage Remediation Strategy

To address these challenges, our Sykes Pumps team deployed a bespoke, integrated system designed for high-performance hydrocarbon removal by dividing the process into three key stages.

1. Groundwater & Surface‑Water Extraction

We utilised an AFPK1042 electric submersible wastewater pump to extract contaminated water from interceptor chambers, inspection pits, and excavations.

The AFPK1042 submersible wastewater pump was selected for this project due to its proven reliability in demanding wastewater and environmental remediation applications.

Designed for use in small pumping stations and utility networks, the pump is well suited to handling contaminated groundwater and surface water encountered during underground tank leak incidents.

2. Rapid‑Deployment

To achieve discharge consent requirements, the team processed pumped flows through a multi-stage treatment line. This included an oil separation stage using coalescing media to agglomerate fine biofuel droplets, achieving over 95% removal of free-phase hydrocarbons. Removing the bulk of the fuel at this stage prevented downstream fouling of the polishing units.

3. Filtration Polishing

The final stage addressed dissolved organics and FAME residues using a GAC system. Arranged in a twin-vessel duty/standby configuration, the system ensured uninterrupted flow and high reliability. High-iodine carbon media was used to adsorb light biofuel fractions, reducing dissolved hydrocarbons to below 0.1 mg/L and delivering a 70% reduction in COD.

Proven Environmental Protection

Over a seven-day operational period, the temporary water treatment system delivered consistent and exceptional performance throughout the tank replacement works. Sykes Pumps discharged all treated water without visible sheen, ensuring it remained fully compliant with regulatory standards throughout the remediation process.

| Parameter | Post‑Leak, Pre‑Treatment | After Oil Separator | After GAC Polishing | Compliance Result |

| Free Hydrocarbons | 150 – 300 mg/L | < 10 mg/L | < 1 mg/L | PASS |

| Dissolved Hydrocarbons | 12 – 25 mg/L | 7 – 12 mg/L | < 0.1 mg/L | PASS |

| COD | 250 – 420 mg/L | 180 – 260 mg/L | 60 – 100 mg/L | PASS |

| FAME Fraction | Detectable | Reduced | Non‑detectable | PASS |

| Visible Sheen | Heavy | Trace | None | PASS |

The Value of Temporary Water Treatment for UST Incidents

The rapid deployment of a temporary water treatment solution prevented contamination from reaching surface water outfalls and the public drainage network. By combining effective oil separation with advanced polishing stages, the client was able to rapidly contain contamination, maintain operational continuity, and achieve full regulatory compliance.

Client Feedback:

“The temporary treatment system was deployed incredibly fast and prevented what could have been a major environmental incident. The combined oil separation and polishing stages handled both free oils and dissolved biofuel contamination with outstanding reliability.”

As a result, the operator now recommends this approach as part of their emergency spill response strategy for all underground storage tank incidents involving hydrocarbons and biofuels.

Download Case Study

Need a reliable pumping or water treatment solution?

|

Sykes Pumps are here to support your overpumping requirements for the Water and Wastewater Treatment sector. Our teams provide the specialist equipment and expertise to keep you compliant and operational.

Speak to our team today! Call 0800 211 611 or visit andrews-sykes.com |

|---|

FAQs

Do you provide 24/7 support during the hire period?

Yes. Sykes Pumps provides round-the-clock technical support. If site conditions change or equipment requires maintenance, our engineers are available 24/7, 365 days a year to ensure your site remains protected.

Is your equipment suitable for other types of contaminants?

Absolutely. Beyond hydrocarbons, our water treatment hire range can address suspended solids (silt), high/low pH levels, and other industrial pollutants.

For more detailed examples of how we handle diverse contamination and dewatering challenges, explore our recent case studies:

➣ Environmental Restoration: Reliable Dewatering and Safe Water Treatment in West Sussex – We successfully managed heavy siltation during a major lake restoration project in West Sussex. Read the full story!

➣ Utility Infrastructure: Overpumping Solution for Major Sewage Treatment Works – Our team delivered a high-volume overpumping solution for a major Sewage Treatment Works, managing critical wastewater bypasses.

➣ Civil Engineering: Dewatering Operations for New South East Reservoir Construction – Large-scale groundwater control was essential for the New South East Reservoir construction, where we navigated complex geological conditions.